Complete Fulfillment Control

Manage the entire order fulfillment process from picking to shipping. Generate labels, print packing slips, and track order progress all in one place.

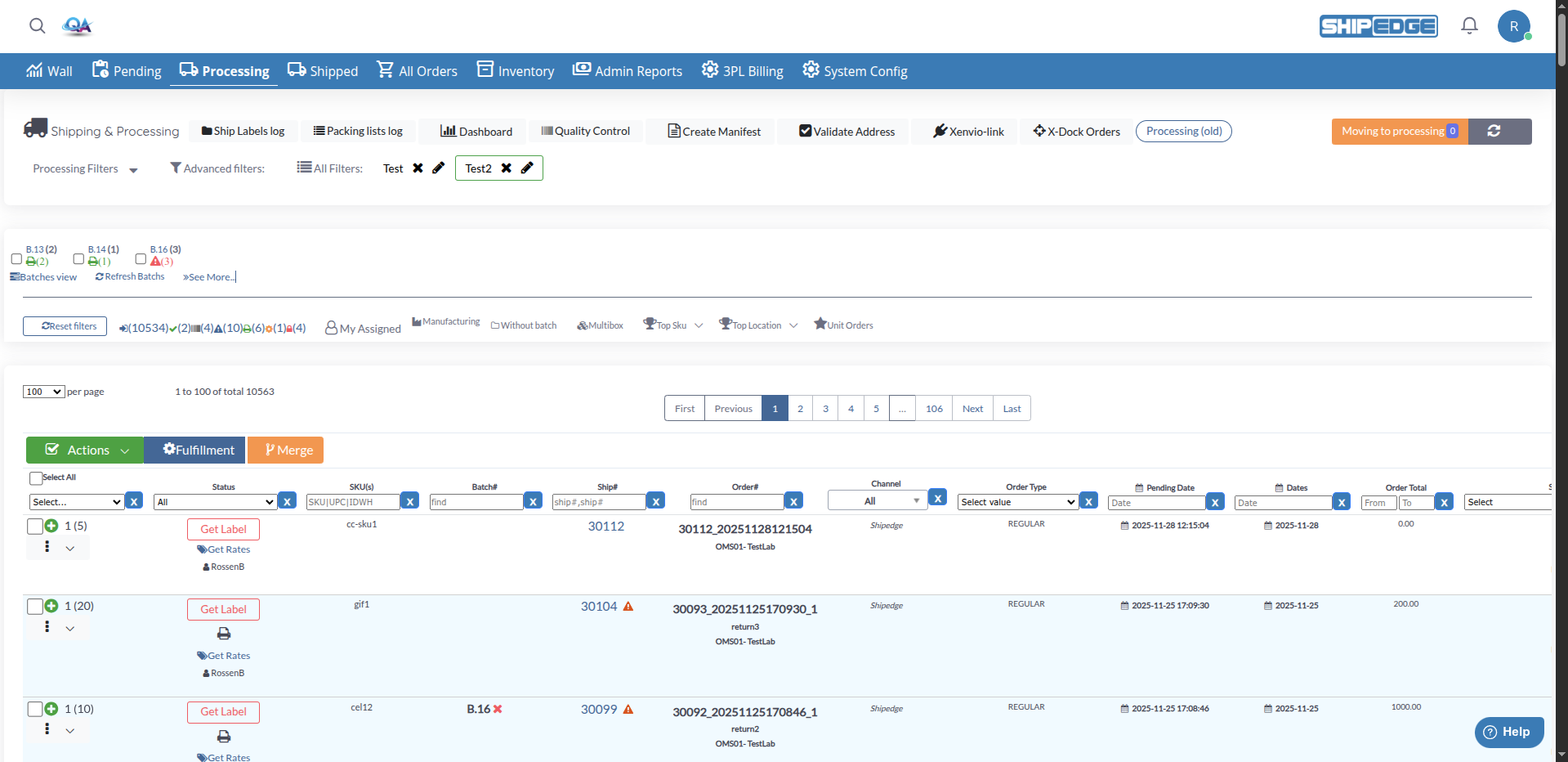

Processing Orders (also called “Shipping & Processing”) shows all orders with status “Processing” (OrderStatus = 4) that are actively being picked, packed, and prepared for shipment in the warehouse. This is where you complete the fulfillment workflow by generating shipping labels, printing packing slips, and managing order actions.

Manage the entire order fulfillment process from picking to shipping. Generate labels, print packing slips, and track order progress all in one place.

Process multiple orders together using batch operations. Generate shipping labels in batches, print multiple packing lists, and manage bulk actions efficiently.

Access Quality Control tools directly from processing orders. Verify package contents, check weights, and ensure orders meet shipping requirements.

Filter orders by account, shipping method, carrier, order type, label status, and many other criteria to focus on specific order groups.

Navigate to Shipping & Processing

Click Shipping & Processing in the warehouse navigation menu. The page loads showing all orders with status “Processing”.

View Order Table

Browse the table showing key information: Ship#, Account, Order#, Reference#, Order Type, Shipping Carrier, Shipping Method, Customer details, Package information, Label status, and more.

Filter Orders

Use the filter options at the top to narrow down orders by account, shipping method, carrier, order type, label status, or other criteria.

Process Orders

Select orders and use the Actions menu to generate labels, print packing lists, or perform other fulfillment tasks.

Located at the top of the page:

View history of all shipping labels generated. Access label logs to review past shipments and reprint labels if needed.

View history of all packing lists printed. Track which orders have had packing slips generated.

Open the processing dashboard to view statistics, order counts, and fulfillment metrics.

Open Quality Control interface to verify package contents, check weights, and validate shipping requirements.

Generate shipping manifests for carriers. Group multiple shipments together for carrier pickup or drop-off.

Verify shipping addresses meet carrier requirements. Check residential vs commercial addresses and validate address format.

Configure Xenvio shipping integration settings. Manage carrier connections and shipping method preferences.

The processing orders table displays the following information:

Click the actions menu (⋮) on any order row to access:

Available for All Orders:

Select multiple orders using checkboxes, then perform bulk operations:

Batch Labels:

Retry Get Labels:

Remove Batch Labels:

Assign User (Managers only):

Basic Filters:

Advanced Filters: Click Advanced filters button to access additional filtering options:

All Filters: Click All Filters button to see and manage all active filters at once.

Some orders may show special actions that need to be completed before shipping:

Print special packing slip format required for certain orders. Click the action button to generate and print.

Generate GS1-128 barcode labels for SPS orders. Required for certain shipping methods or carriers.

Mark order as ready for shipping. Prepares the order for label generation and final processing.

Enter or update serial numbers for items that require serial tracking. Required for certain product types.

Print FBA (Fulfillment by Amazon) SKU labels. Required for Amazon FBA orders.

Select or edit shipping service for FBA orders. Choose the appropriate Amazon shipping method.

Select Order

Find the order you want to generate a label for in the table.

Open Actions Menu

Click the actions menu (⋮) on the order row.

Generate Label

The label generation process depends on your configuration. Labels may generate automatically or require manual action.

Print Label

Once generated, click to print the shipping label.

Select Multiple Orders

Check boxes next to all orders you want to include in the batch.

Open Actions Menu

Click the Actions dropdown button (green button with checkmark icon).

Select Batch Labels

Click Batch Labels from the dropdown menu (or press Alt+B).

Wait for Processing

The system generates labels for all selected orders. A progress indicator shows processing status.

Review Results

Check which orders successfully generated labels and which may need attention.

If label generation fails for some orders:

Identify Failed Orders

Look for orders with label status indicating failure or error.

Select Failed Orders

Check boxes next to orders that need retry.

Retry Get Labels

Click Actions → Retry Get Labels (or press Alt+T).

Wait for Processing

The system attempts to generate labels again for selected orders.

Find Order

Locate the order in the processing table.

Open Actions Menu

Click the actions menu (⋮) on the order row.

Select Print Packing List

Click Print Packing List from the menu.

The packing slip opens in a new window. Print using your browser’s print function.

Instruction lists include picking and packing details:

Select Order

Find the order you need instructions for.

Open Actions Menu

Click the actions menu (⋮).

Select Print Instruction List

Click Print Instruction List from the menu.

Review and Print

Instructions open showing picking locations, items, and packing requirements.

Access Quality Control directly from processing orders:

Select Order

Find the order you want to verify.

Open QC

Click Actions → Web QC or click the Quality Control button in the page header.

Verify Package

In Quality Control, verify:

Complete QC

Mark QC as complete when verification passes.

Temporarily pause an order from processing:

Select Order

Find the order you want to pause.

Open Actions Menu

Click the actions menu (⋮).

Select Pause Ship

Click Pause Ship from the menu.

Confirm Pause

The order is paused and will not process until resumed.

Managers can assign orders to specific warehouse users:

Select Orders

Check boxes next to orders you want to assign.

Open Actions Menu

Click the Actions dropdown button.

Select Assign User

Click Assign User (only visible to managers).

Choose User

Select the user from the dropdown list.

Confirm Assignment

Orders are assigned to the selected user.

Add special services to orders:

Select Order

Find the order you want to add services to.

Open Actions Menu

Click the actions menu (⋮).

Select Value Added Services

Click Value Added Services from the menu.

Choose Services

Select from available services:

Save

Services are added to the order.

Generate shipping manifests for carrier pickup or drop-off:

Click Create Manifest

Click the Create Manifest button in the page header.

Select Orders

Choose which orders to include in the manifest. You can filter by carrier, date, or other criteria.

Generate Manifest

Click to generate the manifest document.

Print or Export

Print the manifest or export for carrier submission.

Filter orders by carrier and process them together. This makes manifest creation easier and reduces carrier-specific errors.

Always use batch label generation for multiple orders. It’s faster and more reliable than individual label generation.

Complete all “Actions Required” items before generating labels. This prevents delays and errors during shipping.

Use Quality Control to verify package contents and weights before generating labels. Catch errors early to avoid shipping mistakes.

Use the Assign User feature to distribute orders evenly among warehouse staff. This improves efficiency and accountability.

Regularly check label status to identify orders that need attention. Retry failed labels promptly to avoid delays.

Problem: Shipping labels fail to generate for some orders.

Solutions:

Problem: Packing list won’t print or shows errors.

Solutions:

Problem: Some orders in a batch didn’t generate labels.

Solutions:

Problem: Action buttons are disabled or don’t work.

Solutions:

Problem: Assign User option doesn’t appear or doesn’t work.

Solutions:

Problem: QC button doesn’t open Quality Control interface.

Solutions:

qualityControl.php if neededNext Steps:

Related Features: