Centralized Management

View all your returns in one place with real-time status updates and quick access to details.

Returns (also called RMA - Return Merchandise Authorization) is the system that allows you to manage product returns from your customers. When a customer needs to return a product, whether due to a defect, order mistake, or simply because they changed their mind, you can create an RMA to track the process from when the customer ships the package until the inventory is added back to stock.

ShipEdge offers a complete returns management system that includes shipping label generation, package status tracking, warehouse processing, and automatic exchange handling.

View all your returns in one place with real-time status updates and quick access to details.

Generate prepaid shipping labels for customers automatically and send them via email with one click.

Monitor the progress of each return from IN-TRANSIT to completed, with automatic carrier updates.

Configure exchanges to automatically send replacement products when the return is received.

Classify returned products as Good or Hurt to maintain accuracy in your inventory.

Handle returns for orders that were shipped via dropshipping or from other warehouses.

The complete flow of a return follows these steps:

Navigate to Returns Module

From the main menu, look for “Returns” and click to access.

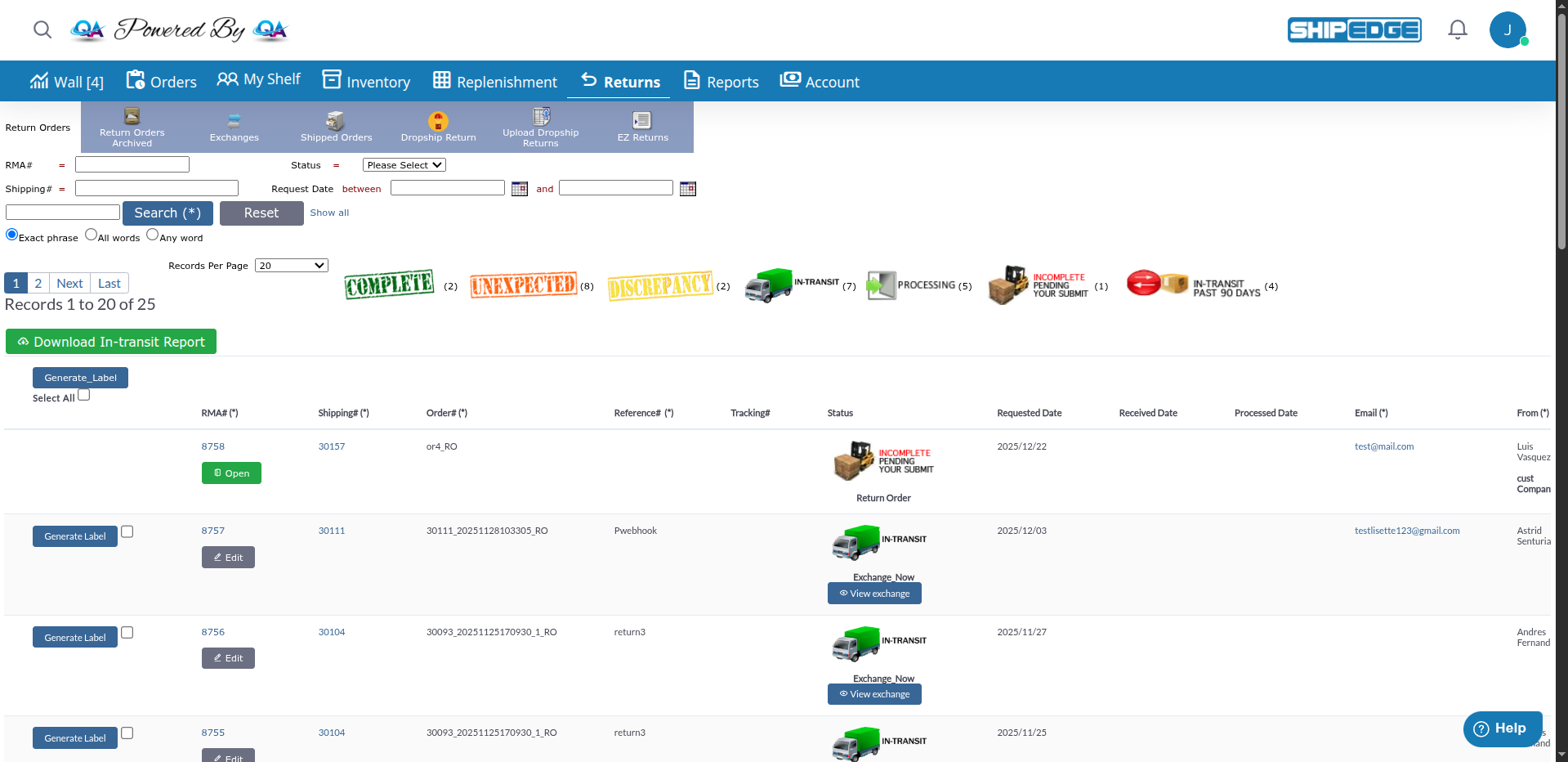

You’ll See the Main Returns View

The system displays:

Available Quick Access Options

At the top you’ll see buttons for:

Meaning: The RMA was created but the label has not yet been sent/generated.

Available actions:

When it occurs: When you create an RMA but don’t generate the label immediately.

Meaning: The customer has already shipped the package and it’s on the way to the warehouse.

Available actions:

When it occurs: After generating the label and the customer ships the package.

Meaning: The package arrived at the warehouse and is being processed.

Available actions:

When it occurs: When the warehouse marks that they received the package.

Meaning: The return was completed successfully. Everything expected was received in good condition.

Result:

When it occurs: When the warehouse processes all items correctly.

Meaning: There is a discrepancy between what was expected and what was received.

Possible reasons:

Available actions:

When it occurs: When the warehouse detects differences during processing.

Meaning: The return is incomplete. Not all expected products were received.

Possible reasons:

Available actions:

When it occurs: When the warehouse receives fewer products than expected.

Meaning: Products were received that were NOT in the original RMA.

Possible reasons:

Available actions:

When it occurs: When the warehouse finds products not listed in the RMA.

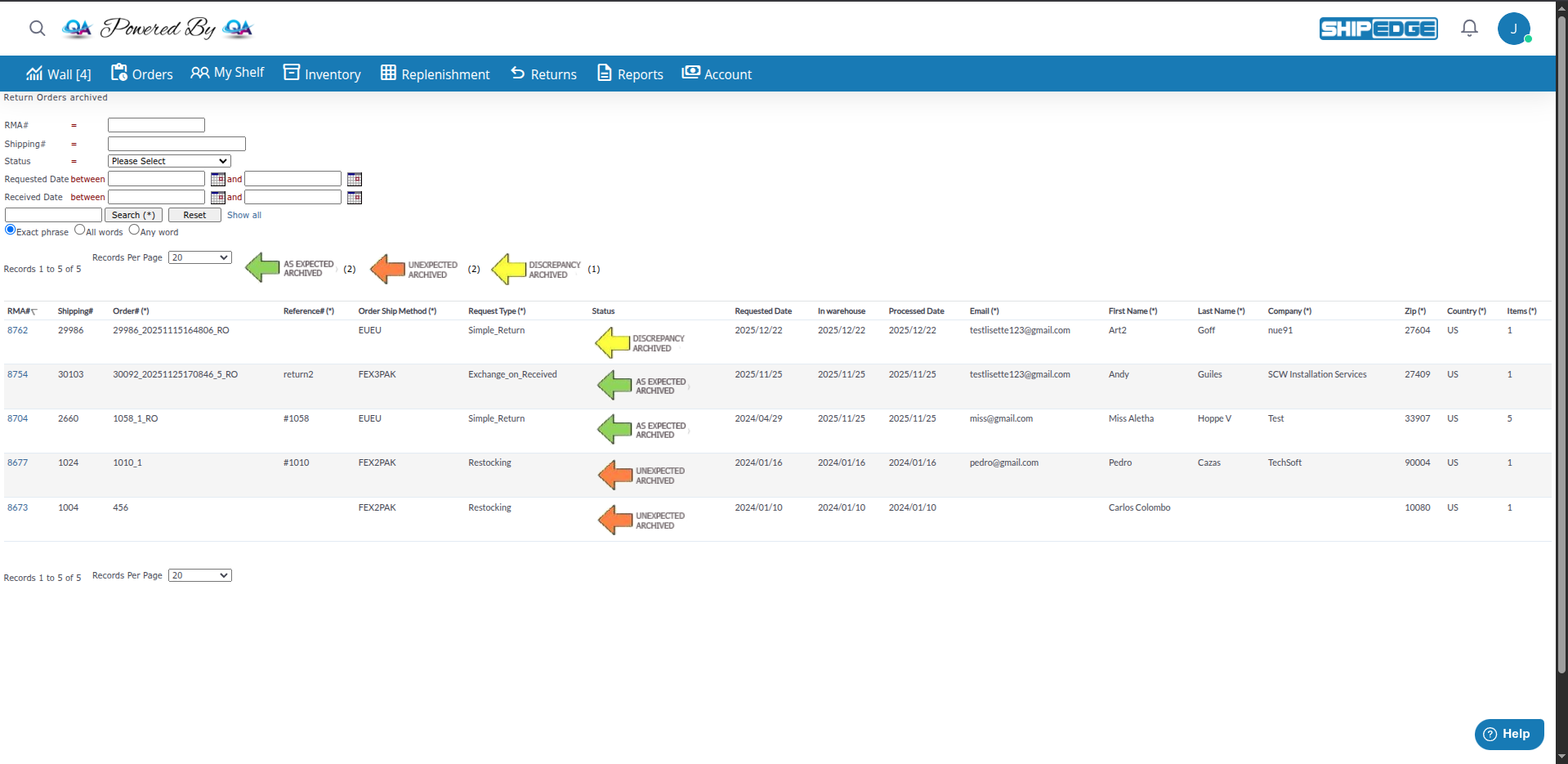

Archived statuses:

Meaning: The RMA was archived and no longer appears in the active list.

Location: View in Return Orders Archived

When it occurs: When you click “Archive” to move the RMA to history.

Simple return where the customer only wants to return the product (usually for refund).

Flow: Customer returns → Inventory updated → End

Standard return initiated from a shipped order.

Flow: Customer returns → Inventory updated → End

Exchange that is processed when the return is received.

Flow: Customer returns → Warehouse receives → Replacement product is sent

Benefit: The customer only receives the new product when they return the original.

Immediate exchange where the replacement product is sent right away.

Flow: Replacement product is sent → Customer returns the original

Benefit: Customer receives the new product faster.

Restocking return, usually from dropshipping or sales channel.

Flow: Returned products are added to inventory

Use: To handle returns from channels like Amazon FBA or dropship.

Return initiated because the carrier returned the package (incorrect address, customer didn’t receive, etc.).

Flow: Carrier returns → Warehouse receives → Inventory updated

The main table shows all active returns with the following columns:

The unique ID of the RMA (Return Merchandise Authorization).

Example: 12345, 67890

Use: Click to view complete RMA details.

The ID of the original order being returned.

Example: 54321

Use: Link to the original order to view history.

The order number from the sales channel.

Example: 123-4567890-1234567 (Amazon), #1234 (Shopify)

The reference of the original order.

Example: CUST-REF-001

Date when the RMA was created.

Format: YYYY/MM/DD

Current status of the RMA (see Return Statuses section above).

Visual icon: Each status has a specific icon.

Tracking number of the return package.

Use: To track where the package is.

Return type (Simple_Return, Exchange, etc.).

See: Return Types section above.

Comments about the RMA added by the user or warehouse.

Example: Customer reported item defective, Missing 1 unit

The view includes advanced filters to find specific RMAs:

Search field: RMA#

Use: Enter the RMA ID to find it quickly.

Status dropdown

Options:

Use: Filter to see only RMAs in a specific status.

Date fields: from and to

Use: Filter RMAs created within a specific date range.

General search field at the top.

Searches in:

When: RMA in PENDING or IN-TRANSIT

How: Click “Generate Label” button in the actions column

Result:

How: Click the RMA# (ID) in the table

You’ll see:

When: RMA in PENDING or IN-TRANSIT

How: Click “Open” (for PENDING) or “Edit” (for IN-TRANSIT) button next to the RMA#

Use: To modify RMA details, add products, or update comments before processing.

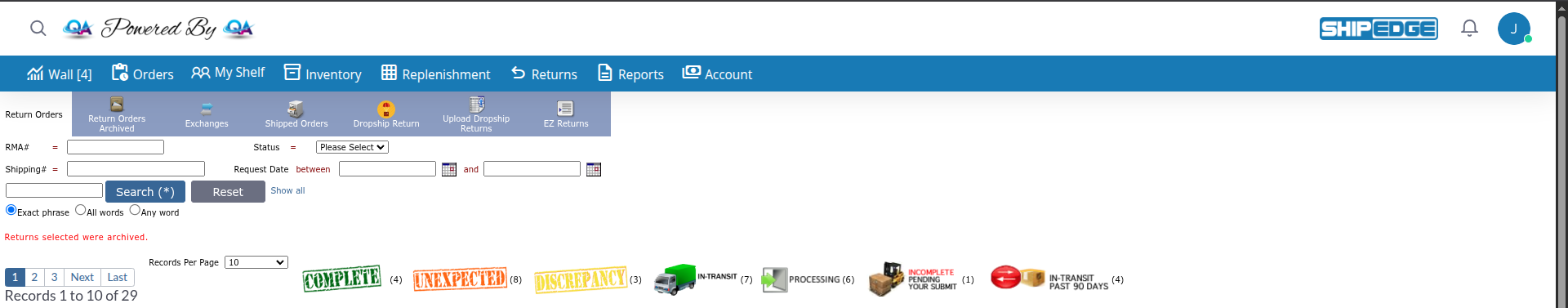

When: RMA completed or resolved

How: Click “Archive” in the actions column

Result: RMA moves to Return Orders Archived

Use: To keep the active list clean and organized.

When: RMA in PENDING or IN-TRANSIT

How: Click “Cancel” button in the actions column

Use: To cancel a return that is no longer needed.

Available: Checkbox to select multiple RMAs

Actions:

Use: To process several RMAs at once.

When you create an RMA, generate the label immediately so the customer can ship the package quickly.

If the customer only wants another size or color, use Exchange_on_Received to save time and shipping costs.

Always add comments explaining why the RMA was created. It helps the warehouse and for future reference.

Monitor RMAs that have been in transit for a long time. If it’s been over 2 weeks, investigate with the carrier.

Move completed RMAs to archived regularly to keep the active list clean and easy to review.

Filter by PROCESSING to see what’s ready for the warehouse, or DISCREPANCY to identify issues.

Problem: The “Initiate return” button doesn’t appear or is disabled.

Possible Causes:

Solutions:

Problem: I click generate label but nothing happens or it gives an error.

Common Causes:

Solutions:

Problem: The RMA has been in IN-TRANSIT for more than 2 weeks.

Causes:

Solutions:

Problem: The warehouse marked DISCREPANCY but it’s not clear what to do.

Causes:

Solutions:

| Aspect | Active Returns | Archived Returns |

|---|---|---|

| Statuses | PENDING, IN-TRANSIT, PROCESSING, DISCREPANCY, INCOMPLETE, UNEXPECTED | AS EXPECTED ARCHIVED, DISCREPANCY ARCHIVED, INCOMPLETE ARCHIVED, UNEXPECTED ARCHIVED |

| Actions | Can be processed, edited, archived, canceled | Read-only (usually) |

| Purpose | Work in progress | History and audit |

| Quantity | A few (current RMAs) | Thousands (all history) |

| Filters | By status, date, tracking | By dates, final status |

See Also:

Related Flow: