Prevent Lost Sales

Keep orders even when inventory is temporarily unavailable. Backorders ensure customers get their products once stock arrives.

Backorders are orders that cannot be fulfilled because products are out of stock. When an order is created but inventory isn’t available, ShipEdge automatically moves it to Backorder. Once inventory is replenished, the system can automatically release backorders and move them to Pending status, ready for fulfillment.

Keep orders even when inventory is temporarily unavailable. Backorders ensure customers get their products once stock arrives.

System automatically releases backorders when inventory becomes available. No manual intervention needed for most cases.

Backorders are processed by priority and order date. Older orders and higher priority orders get inventory first.

Track which products need replenishment by monitoring backorders. See which SKUs are causing delays.

Orders automatically become backorders when:

Instock = 'N' (not in stock)Instock = 'N'Backorders automatically move to Pending when:

Instock = 'Y'The system processes backorders in priority order:

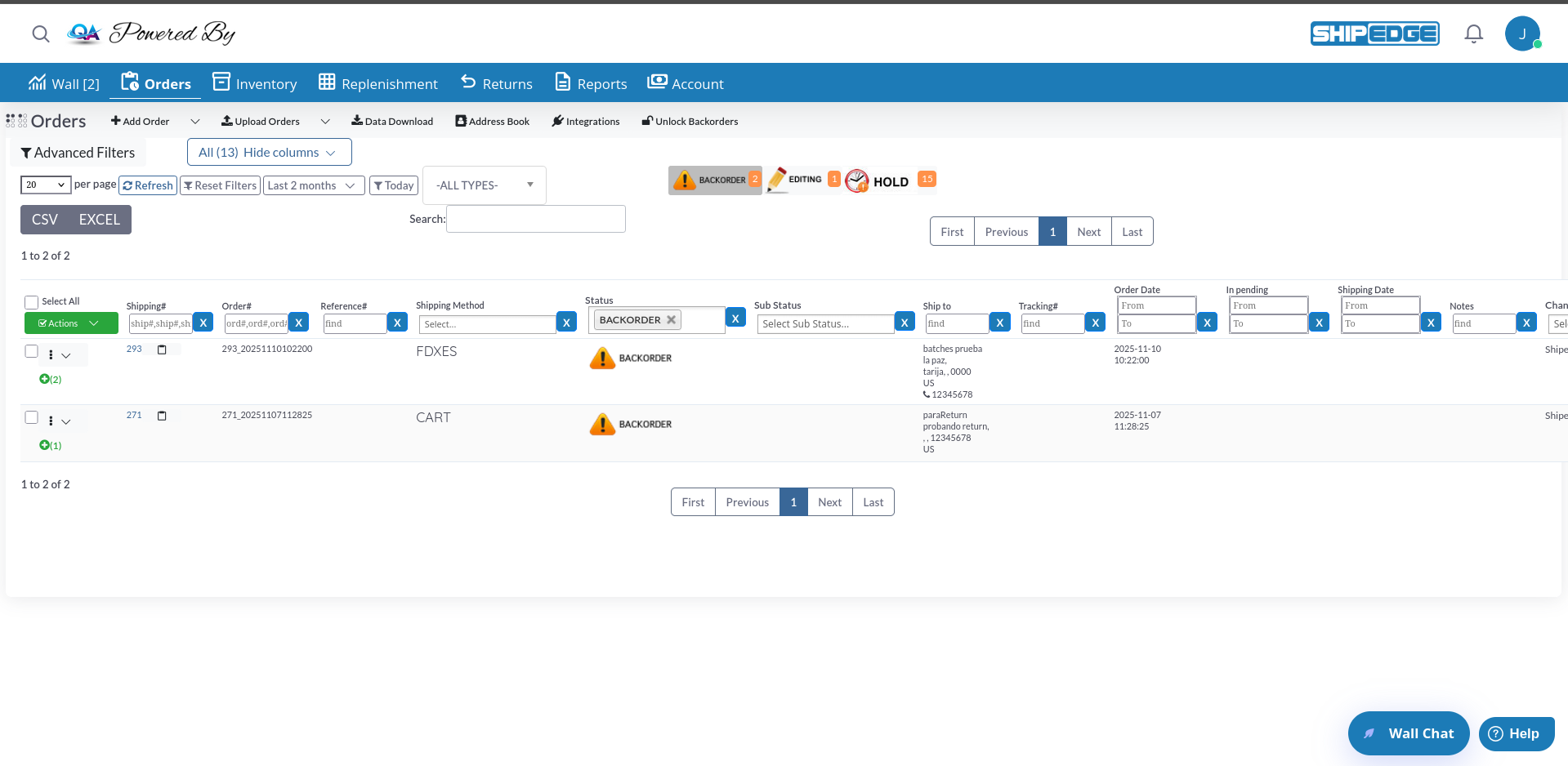

Navigate to Orders View

Go to Orders in the main menu.

Filter by Backorder Status

Click the Backorder alert button at the top of the page.

Review Backorder Details

In the filtered view, you’ll see:

Check Individual Orders

Click any order to view details:

The system automatically releases backorders when:

Process:

Instock = 'Y'When backorders have some products available but not all:

Check for Unlockable Backorders

Look for the Unlock Backorders button in the Orders view menu. This button appears when:

Click Unlock Backorders

Click the Unlock Backorders button to open the divide orders notification window.

Review Available Orders

The window shows:

Select Orders to Divide

Check the orders you want to process, or click Select All to choose all available orders.

Click Divide

Click Divide to process selected orders:

For backorders with partial inventory:

Select Backorder Orders

In the Orders view, check the boxes for backorder orders you want to process.

Choose Bulk Action

Click Actions dropdown, then select Send what’s available.

Confirm Action

System processes selected orders:

Review Results

System shows which orders were processed:

Use product alternatives for backorders:

Select Backorder Orders

Check boxes for backorder orders that have product alternatives configured.

Choose Apply Alternatives

Click Actions → Apply Alternatives.

Confirm Action

System checks for configured alternatives:

Verify Changes

Review orders to ensure alternatives were applied correctly.

Network backorders are a special type that use network inventory:

For orders using network inventory:

Identify Network Backorders

Network backorders show pendingprocess = 'network_backorder_process' in the orders table.

Select Network Backorders

Check boxes for network backorder orders (up to 200 orders).

Click Divide Network Backorder

Click the Divide Network Backorder button in the Actions menu.

Monitor Progress

System shows progress percentage:

Review Results

Once complete:

If a network backorder gets stuck:

Check Order Alerts daily to see how many backorders exist. High counts may indicate inventory issues.

Review backorders by date. Older orders should be addressed first to maintain customer satisfaction.

Use order priority settings to ensure important orders get inventory first when stock arrives.

Set up product alternatives for common backorder situations. This helps automatically resolve some backorders.

When backorders increase, check inventory levels for those SKUs. Plan replenishments accordingly.

Regularly check for unlockable backorders. Use “Unlock Backorders” to process partial orders quickly.

When inventory becomes available, backorders are processed in this order:

Order Priority (highest priority first)

Order Date (oldest first)

Order ID (lowest ID first)

When only partial inventory is available:

An order moves from Backorder to Pending when:

Instock = 'Y'Backorders not releasing automatically

Unlock Backorders button not appearing

Backorders stuck in status

pendingprocess statusOrders not becoming backorders when out of stock

Priority not working

If backorders aren’t processing correctly: